Sensors and Leak Detection Systems

Leak detection system Sens8®

Sens8 is a modern, easy-to-use and reliable leak detection control unit, supporting up to 8 sensors of various types. It is an industrial solution that combines proven solutions resulting from the company's many years of experience with a modern approach. The control unit has an intuitive button where you can read the status of each sensor and a button to clear the alarm sound signal. The programming of the control unit and the graphical preview of indications and parameters is done via a dedicated Android application with safe Bluetooth® communication. It has 8 programmable potential-free relay outputs and optional GSM or Modbus communication, so it can also be used as an automation and indication system for any processes that require reading the status of sensors.

It has a closed, self-extinguishing polycarbonate housing with IP66/68 tightness class, alarm history, sensor auto-calibration function, the ability to programmatically change the sensor state, a cable continuity detection system and an application menu in Polish and English. The control unit works with Petroster sensors and many sensors from other manufacturers, such as OPW, VeederRoot and others. It has ATEX JSHP 18ATEX0021X of the highest explosion group II (1) G [Ex ia Ga] IIC.

Float sensor SimpleLeak® ATEX

PETROSTER SimpleLEAK ATEX sensors are devices used to detect leaks of liquid substances using dry or wet methods in systems of categories II, III and V, in accordance with EN 13160-1. Depending on the application, they can also be used as sensors for production processes and other utilities related to detecting changes in the liquid level, such as an overflow sensor. They are dedicated to work with PETROSTER control units, however, they are adapted to work with most available control units. They are reed sensors with a float equipped with a magnet, which is moved along the sensor axis when the liquid level changes and, depending on the state, turns the reed switch on or off. Basically, they are NO sensors for bottom-up operation and NC sensors for top-down operation. The sensor states can be reversed by inverting the float, as shown by the symbols on it. They are equipped with a continuous cable monitoring system, in accordance with the requirements of PN-EN 13160-1, enabling the differentiation of an alarm related to a change in the liquid level or detection of a leak from a damage to the sensor cable.

They are simple devices by definition and construction, which makes them extremely reliable. Made of acid-resistant steel and the use of a float made of resistant, high-displacement material, the SimpleLEAK ATEX sensors can be used with virtually any medium. Additionally, the floats are equipped with protrusions that prevent them from sticking to the body at maximum condition, so they can be used with viscous and relatively high-density media. They are designed in such a way that the hysteresis of operation is as low as possible, thanks to which the sensors have a very high level of reliability of indications.

They are designed to operate in the temperature range from -30oC to +80oC. They meet the requirements of the ATEX 2014/34/EU directive and the PN-EN 60079-0:2013-03 and PN-EN60079-11:2012 standards and can be used in explosion hazard zones, including zone "0" of gas, dust and gas environments. mists of substances of explosion groups up to and including IIC, having a temperature class of T6. The version intended for potentially explosive atmospheres has ATEX no. JSHP 18ATEX0018X of the highest explosion group II 1G Ex ia IIC T6 Ga.

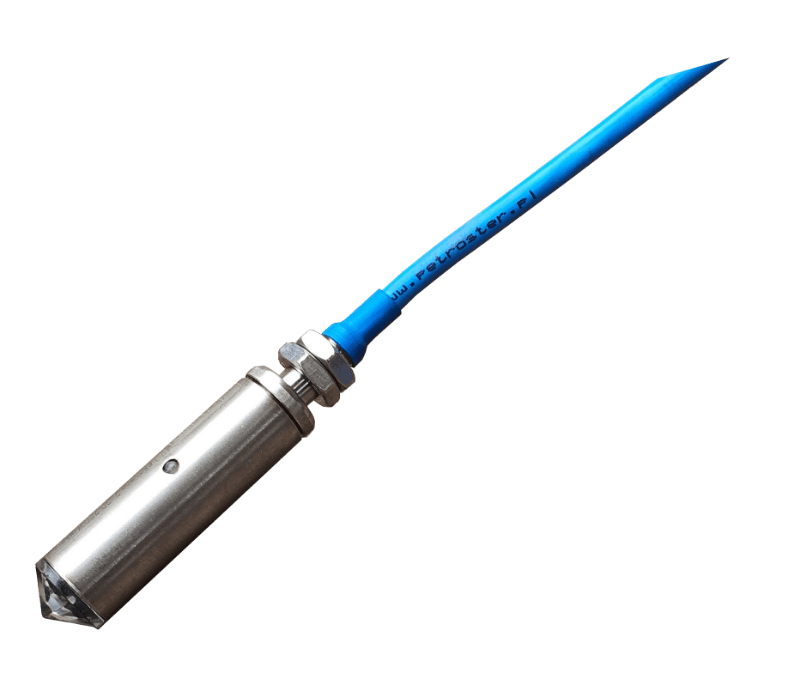

Optical sensor PetroOpt® ATEX

PETROSTER PetroOPT ATEX sensors are optical sensors designed to detect leaks of liquid substances using dry or wet methods in systems of categories II, III and V, in accordance with EN 13160-1. Depending on the application, they can also be used as sensors for production processes and other utilities related to detecting changes in the liquid level, such as an overflow sensor. They are dedicated to work with PETROSTER control units, however, they are adapted to work with most available control units. They are equipped with a continuous cable monitoring system, in accordance with the requirements of PN-EN 13160-1, enabling the differentiation between an alarm related to a change in the sensor status and a damage to the sensor cable. They are optical sensors equipped with a measuring optical system used to detect liquids by changing the refraction of light after the optical element is immersed in the liquid or after its emergence, depending on the application. The unexcited state (not immersed in a liquid) causes a signal in the form of a voltage of approximately 4.5V, and a voltage below 1V occurs when the sensor is excited, i.e. when light is refracted by immersion in a liquid.

They meet the requirements of the ATEX 2014/34/EU directive and the PN-EN IEC 60079-0:2018-09 and PN-EN60079-11:2012 standards and can be used in explosion hazard zones, including zone "0" of gas and dust environments and mists of substances of explosion groups up to and including IIC, with a temperature class of T6 for applications at ambient temperatures up to 75oC and T5 for applications up to 80oC. The version intended for potentially explosive atmospheres has ATEX no. JSHP 20ATEX0065X of the highest explosion group II 1G Ex ia IIC T6…T5 Ga.

Vapour detection sensor PetroVap® ATEX

PETROSTER PetroVAP ATEX sensors are vapor sensors designed to detect leaks of liquid substances or gases using the dry method in category III and V systems, in accordance with EN 13160-1. They are intended mainly for the detection of hydrocarbon vapors, including gasoline, diesel oil, LPG, alcohol, hydrogen and carbon monoxide, as well as other media depending on their physicochemical properties and volatility. They are catalytic combustion sensors with high sensitivity and short response time, using the phenomenon of changing the sensor's output resistance depending on the number of vapor particles in the vicinity of the sensor. The output voltage from the sensor increases in proportion to the increase in the detected vapor concentration, ranging from 0.2V at the neutral state to 5.5V when the maximum detection threshold of the sensor is reached. The sensors have a built-in diode in the body, signaling the active power supply of the sensor and the excitation level, changing the color of the diode in proportion to the increase in the detected vapor concentration, from green in the neutral state to red when the upper threshold of the detection range is reached.

They are dedicated to work with PETROSTER control units, but are adapted to work with most control units available on the market. They are equipped with a continuous cable monitoring system, in accordance with the requirements of PN-EN 13160-1, enabling the differentiation between an alarm related to a change in the vapor level or the detection of a leak and a damage to the sensor cable. Depending on the application, they can also be used as sensors for production processes. They are devices with the simplest possible structure, based on a measuring element with high measurement reliability, made using industrial technology, thanks to which they are characterized by high reliability and failure-free operation. They are designed in such a way that the hysteresis of operation is as low as possible, which is why they have a very high level of reliability of indications. The body is made of acid-resistant steel, the measuring element is made using industrial technology and the IB class cable enables the use of PetroVAP ATEX sensors with a wide range of media. They are designed to operate in the temperature range from -30oC to +80oC.

They meet the requirements of the ATEX 2014/34/EU directive and the PN-EN IEC 60079-0:2018-09 and PN-EN60079-11:2012 standards and can be used in explosion hazard zones, including zone "0" of gas and dust environments and mists of substances of explosion groups up to and including IIC, with a temperature class of T6 for applications at ambient temperatures up to 75oC and T5 for applications up to 80oC. The version intended for potentially explosive atmospheres has ATEX no. JSHP 20ATEX0005X of the highest explosion group II 1G Ex ia IIC T6…T5 Ga.

contact us

Please contact us. Our team is at your disposal.