Breather Valves

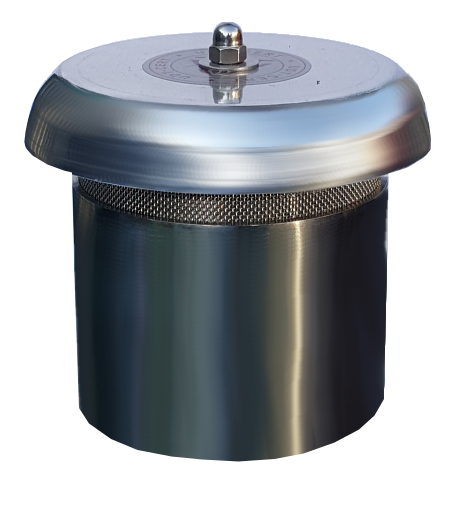

without Flame Arresters

Breather Valves EFA

EFA valves are the most popular model in the offer of valves without a flame arrester. They come in sizes from DN50 to DN300. This is a modern design dedicated to storage and process tanks requiring balanced aeration and venting parameters. Their main tasks are to automatically regulate the pressure inside the tanks and prevent spontaneous emission of vapors into the atmosphere. They are class II 1 G c T6 devices, therefore they can be used in any explosion hazard zone. They have discs integrated into one unit, thanks to which they have compact dimensions and low weight. Proportional operating characteristics, no pressure drop below the setting throughout the entire operating range, high tightness and the same valve closing and opening pressure are a number of features that make them suitable for use with demanding installations, including nitrided and metered installations.

The design of EFA valves is based on high-performance industrial solutions, thanks to which they are characterized by high throughput, high tightness and failure-free operation. Thanks to being made entirely of 316L acid-resistant steel without additional seals, they have no elements that require periodic replacement, and can be used with virtually any medium, including food media. They are available in Standard and High Flow versions, as well as in an individual Special version. A number of unique features and technologies used make them one of the smallest, least reliable and technically newest valves on the market. They are also available in a version with integrated double-wall heating, also in the ATEX version.

The EFA series breathing valves meet the requirements of the ATEX 2014/34/EU directive and are in accordance with the following standards: PN-EN 1127-1, EN 13463-1, PN-EN 13463-5 and PN-EN ISO 28300. They have an EU declaration of conformity.

Breather Valves RFA

RFA is a series of breathing valves without a flame arrester, available in sizes from DN50 to DN300 and dedicated to installations requiring high inhalation capacity. They have discs integrated into one unit, as in the case of EFA, but their disc proportions have been reversed to obtain the highest possible vacuum throughput parameter. Their main tasks are to automatically regulate the pressure inside the tanks and prevent spontaneous emission of vapors into the atmosphere. They are class II 1 G c T6 devices, therefore they can be used in any explosion hazard zone. They have discs integrated into one unit, thanks to which they have compact dimensions and low weight.

RFA series breathing valves meet the requirements of the ATEX 2014/34/EU directive and are in accordance with the following standards: PN-EN 1127-1, EN 13463-1, PN-EN 13463-5 and PN-EN ISO 28300. They have an EU declaration of conformity.

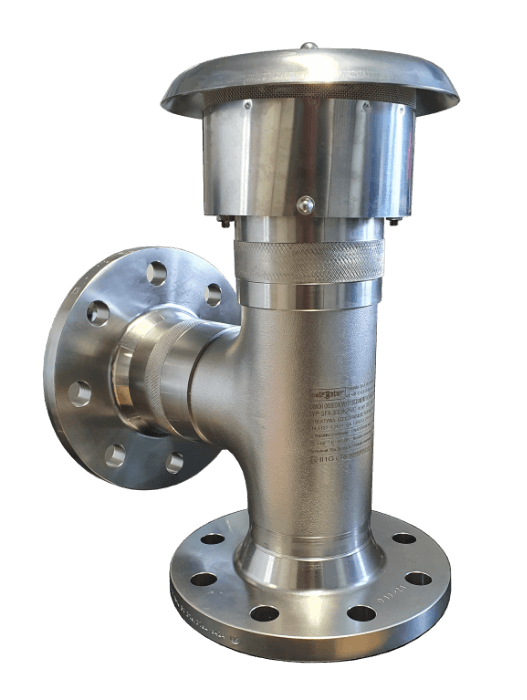

Breather Valves SFA

SFA is a series of breathing valves with a three-way design, dedicated to specialized applications and installations operating in closed vapor circulation. Unlike EFA and RFA, SFA valves have separated overpressure and underpressure discs, which allows for an individually selected ratio of the inhalation and exhalation operating parameters to each other and the use of a closed circuit (e.g. discharge of vapors into the pipeline). Their main tasks are to automatically regulate the pressure inside the tanks and prevent spontaneous emission of vapors into the atmosphere. They are class II 1 G c T6 devices, therefore they can be used in any explosion hazard zone. Proportional operating characteristics, no pressure drop below the setting throughout the entire operating range, high tightness and the same valve closing and opening pressure are a number of features that make them suitable for use with demanding installations, including nitrided and metered installations. The design of SFA valves is based on high-performance industrial solutions, thanks to which they are characterized by high throughput, high tightness and failure-free operation.

Thanks to being made entirely of 316L acid-resistant steel without additional seals, they have no elements that require periodic replacement, and can be used with virtually any medium, including food media. They are available in Standard and High Flow versions, as well as in an individual Special version. A number of unique features and technologies used make them one of the smallest, least reliable and technically newest valves on the market. They are also available in a version with integrated double-wall heating, also in the ATEX version.

The SFA series breathing valves meet the requirements of the ATEX 2014/34/EU directive and are in accordance with the following standards: PN-EN 1127-1, EN 13463-1, PN-EN 13463-5 and PN-EN ISO 28300. They have an EU declaration of conformity.

contact us

Please contact us. Our team is at your disposal.