Flame Arresters

Detonation type

Flame arresters

Deflagration type Flame Arresters

Deflagration flame arresters are basic safeguards that prevent flame from entering an installation containing flammable vapors. They are installed at the ends of pipelines or on a part located close to its end, where there is no risk of detonation developing. They provide protection against deflagration conditions, i.e. the explosion phase whose propagation does not exceed the speed of sound. They are usually used at the ends of vent pipelines, at fume collection connections and wherever potential ignition may occur. Deflagration flame arresters generally have lower flow resistance than detonation flame arresters.

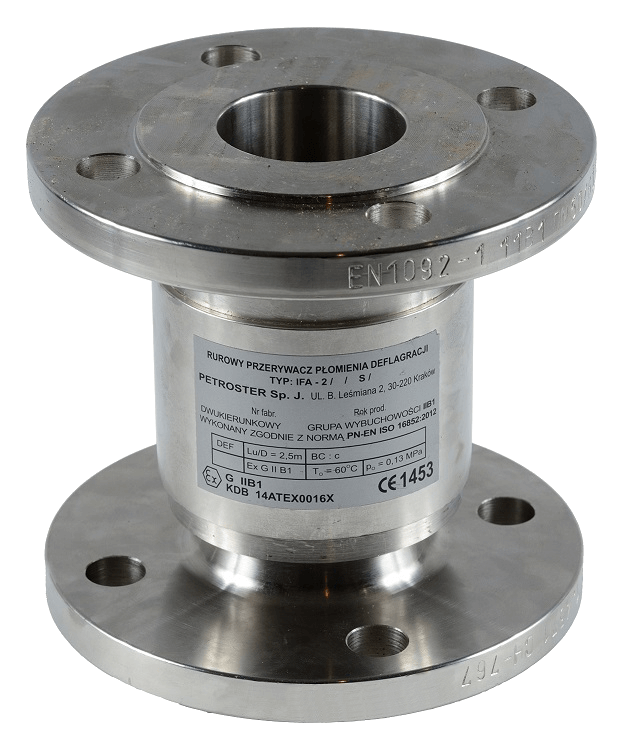

Deflagration type Flame Arresters IFA

IFA - deflagration flame arresters of the IFA series are bidirectional fuses, tested as protection against deflagration conditions of explosion groups IIA and IIB (including groups IIA1, IIB1, IIB2 and IIB3). They are available as end devices, pipe devices with a specified maximum distance from the end of the pipeline, and end devices with EFA, RFA and SFA breathing valves. They are dedicated to demanding installations of the petrochemical market, including aviation fuels and alcohols, as well as all installations of the broadly understood industry. They are produced in various capacity versions and connection diameters from DN10 to DN200. They are available with various types of connections, including threaded, flange and tri-clamp, so they can be used in virtually every industry sector.

They are characterized by high throughput, failure-free operation and small dimensions. They are made entirely of 316L acid-resistant steel and chemically passivated, making them resistant to all types of media, including aggressive substances. The flame arrester barriers are additionally electropolished, which makes them less susceptible to dirt and makes them easier to clean. This increases the level of security and reduces service costs. Optionally, they can be equipped with built-in double-wall Ex heating and various types of sensors, including temperature, pressure, flame and other sensors.

The fuses meet the requirements of the ATEX 2014/34/EU directive and are manufactured in accordance with the following standards: PN-EN ISO 16852 and PN EN 1127-1. They have an EC Type Examination Certificate No. KDB 14ATEX0016X from the Central Mining Institute of the "BARBARA" Experimental Mine.

Detonation flame arresters

Detonation flame arresters, unlike deflagration flame arresters, do not prevent the flame from entering the pipeline, but serve to protect the most important elements of the installation against the detonation generated in the pipeline entering them, and also prevent the spread of detonation between the system elements. They are used in the place closest to the protected element, such as storage tanks or wherever the distance from the expected ignition source indicates that detonation may occur. The purpose of a detonation flame arrester is not only to prevent the flame from passing through and suppress the explosion, but also the shock wave accompanying the detonation.

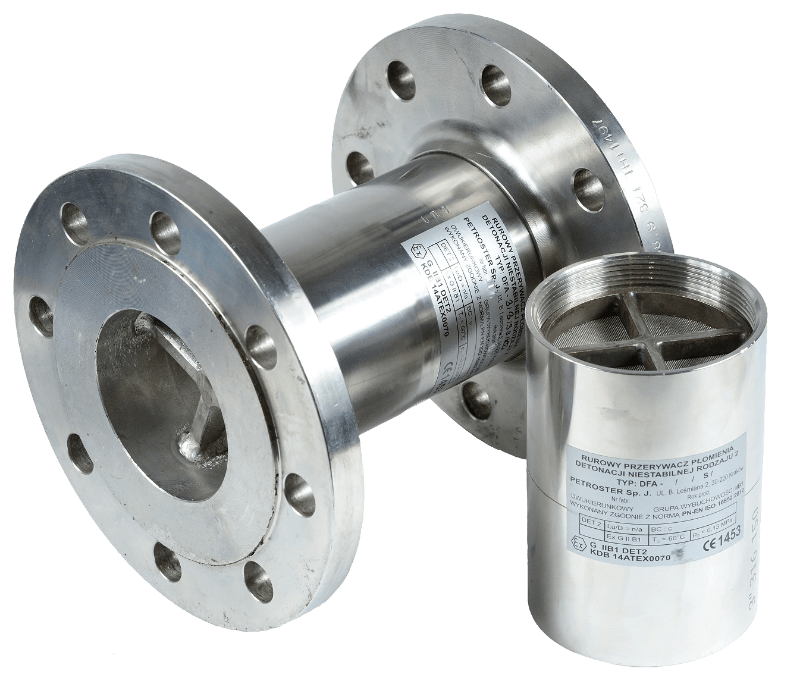

Detonation type Flame Arresters DFA

DFA - DFA series detonation flame arresters are bidirectional fuses, tested as protection against unstable detonation conditions of explosion groups IIA and IIB1. They are dedicated to demanding installations of the petrochemical market, including aviation fuels and alcohols, as well as all installations of the broadly understood industry. They are produced in various capacity versions and connection diameters from DN10 to DN150. They are available with various types of connections, including threaded and flanged, so they can be used in virtually every industry sector.

They are characterized by relatively high throughput, failure-free operation and small dimensions. They are made entirely of 316L acid-resistant steel and chemically passivated, making them resistant to all types of media, including aggressive substances. The flame arrester barriers are additionally electropolished, which makes them less susceptible to dirt and makes them easier to clean. This increases the level of security and reduces service costs. Optionally, they can be equipped with built-in double-wall Ex heating and various types of sensors, including temperature, pressure, flame and other sensors.

The fuses meet the requirements of the ATEX 2014/34/EU directive and are manufactured in accordance with the following standards: PN-EN ISO 16852 and PN EN 1127-1. They have an EC Type Examination Certificate No. KDB 14ATEX0070 from the Central Mining Institute of the "BARBARA" Experimental Mine.

contact us

Please contact us. Our team is at your disposal.