Breather Valves

with Flame Arresters

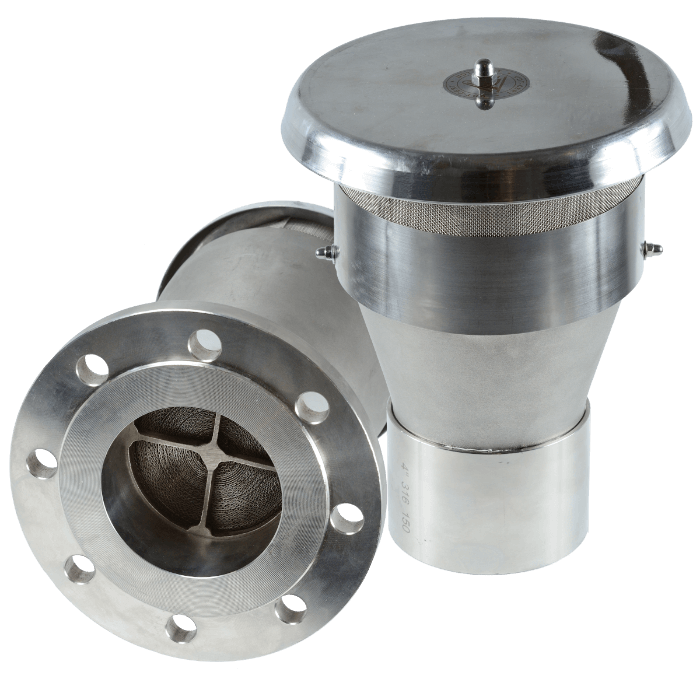

Breather Valves IFA+EFA

IFA+EFA valves are currently the most popular model in the Petroster valve offer. They are produced in connection diameters from DN50 to DN200 and various capacity versions. This is a modern design combining a breathing valve with a flame arrester in one device, dedicated to storage and process tanks with flammable media requiring balanced aeration and venting parameters. Their main tasks are to protect pipelines and tanks against fire entering them, automatically regulate the pressure inside the tanks and prevent spontaneous emission of vapors into the atmosphere. They have been tested and approved as protection against deflagration conditions for gas mixtures, vapors and mists of substances classified into explosion groups IIA, IIB1 and IIB (including group IIB3).

They have discs integrated into one unit, thanks to which they have compact dimensions and low weight. Proportional operating characteristics, no pressure drop below the setting throughout the entire operating range, high tightness and the same valve closing and opening pressure are a number of features that make them suitable for use with demanding installations, including nitrided and metered installations. The designs of the breathing valve and flame arrester are based on highly efficient industrial solutions, thanks to which they are characterized by high throughput. Thanks to being made entirely of 316L acid-resistant steel without additional seals, they have no elements subject to periodic replacement, and can be used with virtually any medium, including fuels, biofuels and their components, aviation and ship fuels, alcohols, solvents, resins and others. They are available in Standard and High Flow versions, as well as in an individual Special version. A number of unique features and technologies used make them one of the smallest, least reliable and technically newest valves on the market.

They are also available in a version with integrated double-wall heating, also in the ATEX version. The IFA+EFA series breathing valves meet the requirements of the ATEX 2014/34/EU directive and are in accordance with the following standards: PN-EN ISO 16852, PN-EN 1127-1, EN 13463-1, PN-EN 13463-5 and PN-EN ISO 28300.

They have an EC Type Examination Certificate number KDB 14ATEX0016X from the Central Mining Institute of the Experimental Mine "BARBARA" and an EU declaration of conformity.

Breather Valves IFA+RFA

IFA+RFA valves are modern devices combining a breathing valve with a flame arrester in one device, which are dedicated to applications requiring high inhalation capacity. They have discs integrated into one unit, as in the case of IFA+EFA, but their disc proportions have been reversed to obtain the highest possible vacuum throughput parameter. They are available in connection diameters from DN50 to DN200 and in various capacity versions. Their main tasks are to protect pipelines and tanks against fire entering them, automatically regulate the pressure inside the tanks and prevent spontaneous emission of vapors into the atmosphere. They have been tested and approved as protection against deflagration conditions for gas mixtures, vapors and mists of substances classified into explosion groups IIA, IIB1 and IIB (including group IIB3). They have discs integrated into one unit, thanks to which they have compact dimensions and low weight.

Proportional operating characteristics, no pressure drop below the setting throughout the entire operating range, high tightness and the same valve closing and opening pressure are a number of features that make them suitable for use with demanding installations, including nitrided and metered installations. The designs of the breathing valve and flame arrester are based on highly efficient industrial solutions, thanks to which they are characterized by high throughput. Thanks to being made entirely of 316L acid-resistant steel without additional seals, they have no elements subject to periodic replacement, and can be used with virtually any medium, including fuels, biofuels and their components, aviation and ship fuels, alcohols, solvents, resins and others. They are available in Standard and High Flow versions, as well as in an individual Special version. A number of unique features and technologies used make them one of the smallest, least reliable and technically newest valves on the market. They are also available in a version with integrated double-wall heating, also in the ATEX version.

The IFA+RFA series breathing valves meet the requirements of the ATEX 2014/34/EU directive and are in accordance with the following standards: PN-EN ISO 16852, PN-EN 1127-1, EN 13463-1, PN-EN 13463-5 and PN-EN ISO 28300.

They have an EC Type Examination Certificate number KDB 14ATEX0016X from the Central Mining Institute of the Experimental Mine "BARBARA" and an EU declaration of conformity.

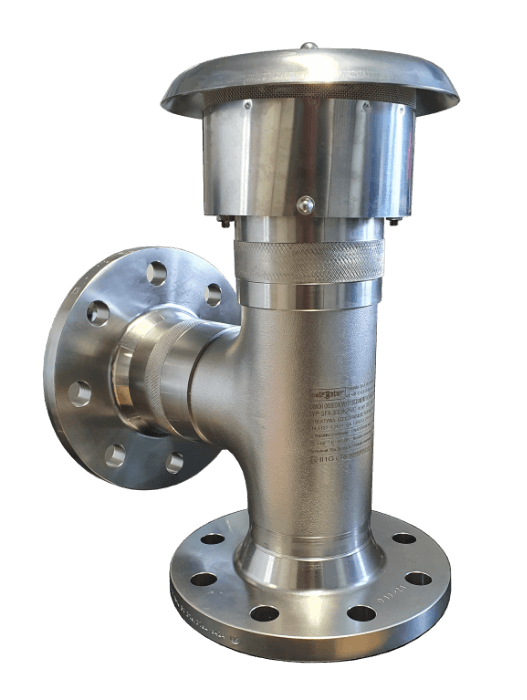

Breather Valves SFA+IFA

SFA+IFA valves are a three-way model with an integrated flame arrester, dedicated to specialized applications and installations operating in closed vapor circulation. They are available in connection diameters from DN50 to DN200 and in various capacity versions. As standard, the valve has a flame arrester on the inhalation, but it can also be additionally equipped with a flame arrester on the exhaust. Unlike IFA+EFA and IFA+RFA, SFA+IFA valves have separate overpressure and underpressure discs, which allows for an individually selected ratio of inhalation and exhalation operating parameters. This also allows the use of a closed vapor circulation system, both in the case of exhalation (ejection of vapors into the pipeline) and inhalation (suction, e.g. from a collector or buffer tank).

Proportional operating characteristics, no pressure drop below the setting throughout the entire operating range, high tightness and the same valve closing and opening pressure are a number of features that make them suitable for use with demanding installations, including nitrided and metered installations. The designs of the breathing valve and flame arrester are based on highly efficient industrial solutions, thanks to which they are characterized by high throughput. Thanks to being made entirely of 316L acid-resistant steel without additional seals, they have no elements subject to periodic replacement, and can be used with virtually any medium, including fuels, biofuels and their components, aviation and ship fuels, alcohols, solvents, resins and others. They are available in Standard and High Flow versions, as well as in an individual Special version. A number of unique features and technologies used make them one of the smallest, least reliable and technically newest valves on the market. They are also available in a version with integrated double-wall heating, also in the ATEX version.

The IFA+RFA series breathing valves meet the requirements of the ATEX 2014/34/EU directive and are in accordance with the following standards: PN-EN ISO 16852, PN-EN 1127-1, EN 13463-1, PN-EN 13463-5 and PN-EN ISO 28300.

They have an EC Type Examination Certificate number KDB 14ATEX0016X from the Central Mining Institute of the Experimental Mine "BARBARA" and an EU declaration of conformity.

contact us

Please contact us. Our team is at your disposal.