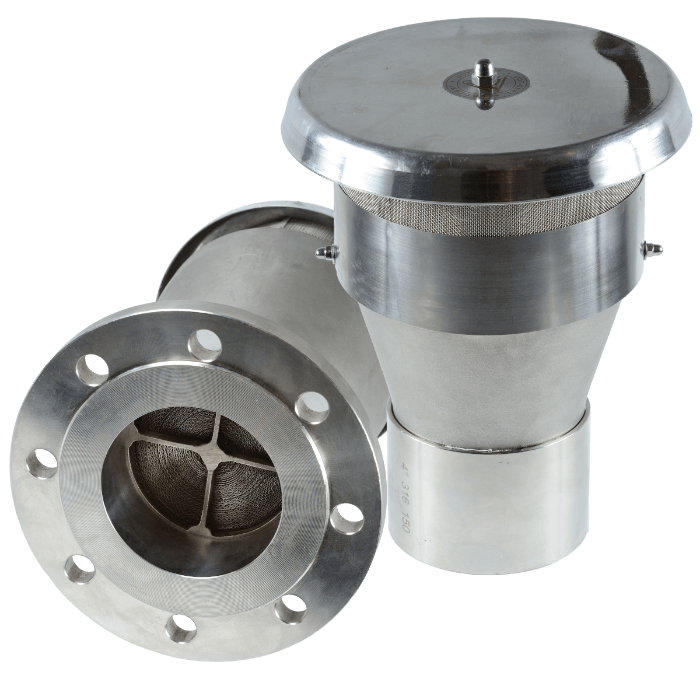

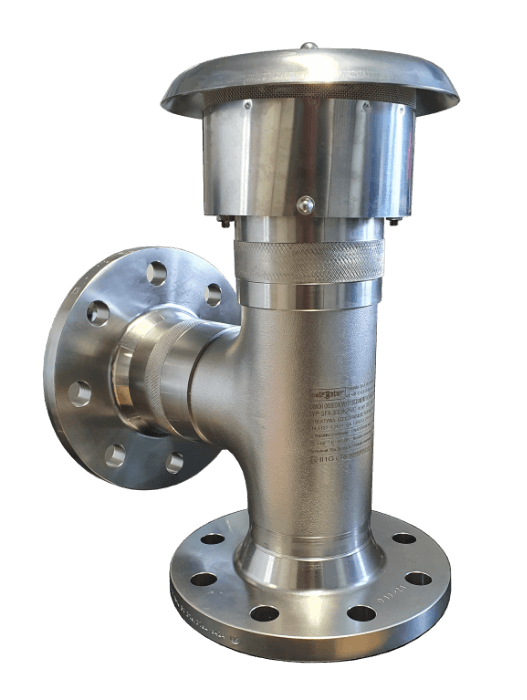

Breather Valves

The tasks of breather valves are to automatically regulate the pressure inside the tanks, preventing the pressure or negative pressure in the installation from increasing beyond the values accepted as safe and permissible, and preventing spontaneous emission of vapors into the atmosphere.

In the version with a flame arrester, they also protect against fire entering the pipeline. Petroster breathing valves are used in the petrochemical, chemical, food and aviation industries. The devices are available in standard versions, with increased capacity and individual versions. A number of unique features and technologies used, as well as a non-standard approach to production make Petroster breathing valves one of the most advanced, and at the same time the smallest and least failure-proof valves on the market.

A different production approach from Petroster

Petroster breathing valves are an innovative design that presents a completely different construction approach than other valves available on the market. The devices are not based on large, heavy and cast bodies, but are manufactured from commercially available components, creating as small and light devices as possible. The main element of the valve is not the body, as in the case of other designs, therefore production is not limited in any respect by ready-made housings. This allows for a fully flexible approach to production, both in technical and quantitative terms. Production is focused on functional features, operating characteristics and technologies used, as priority issues in terms of use and safety.

Thanks to this different approach, the user not only does not have to pay for large and heavy castings, but also receives a product always made using the latest technologies and solutions at an affordable price.

Full production flexibility allows for any changes to be introduced on an ongoing basis, as well as the production of individual, even personalized, customer-specific devices, even in single units. However, the greatest advantage of Petroster valves is a number of unique design and operational features that make their operation less problematic and cheaper than other designs, and the safety level of the protected installation is higher.

Advantages and features of Petroster breather valves

No pressure drop when opening the valve below the pressure setting. Proportional pressure increase with increased flow over the entire operating range - proportional characteristic

- no risk of blow-through in the case of nitrided installations

- no effect of tank ventilation after opening the valve, as in the case of valves with 10% technology

- possibility of opening the valve slightly above the assumed minimum pressure in the tank (e.g. nitrogen cushion pressure), without the risk of falling below this value, which allows for a greater margin of valve operation

- higher operational safety than in other designs, thanks to the larger working range of the valve vacuum

- less material fatigue of the tank, resulting in less susceptibility to microcracks in the long term

The vacuum discs are directed downwards and the weight of the disc is balanced by a spring, which makes it possible to open the vacuum valve with minimal vacuum, even close to zero

- higher operational safety than in other designs, thanks to the larger working range of the valve vacuum

- no increased evaporation of the medium compared to the conditions of increased negative pressure

- less material fatigue of the tank, resulting in less susceptibility to microcracks in the long term

The valve closes at the same pressure as the opening setting

- no risk of blow-through in the case of nitrided installations

The valve discs are sealed using surface-mechanical technology, without any seals

- They thus do not have any components that need to be replaced periodically

- actual, full construction of acid-resistant steel

The valve faces are sealed in three stages, and the final lapping stage is electropolishing of the faces.

- Petroster valves are characterized by extremely high tightness

- are adapted to work with modern installations, in particular with nitrided installations, lower nitrogen losses

As standard, they are made entirely of chemically passivated 316L acid-resistant steel

- they can be used with any medium, including food media, without the need to obtain additional approvals

Adapted to work with modern installations, in particular with nitrided installations

Possibility of installing a flame arrester as an integral part of the breathing valve

- throughput characteristics of one, coherent device, without the need for additional calculations and comparison of the characteristics of two devices

- one inspection protocol, lower service costs, less operational documentation

- ATEX certification as one, integral device

Covers designed to prevent valve freezing. We use an air channel open at the bottom, which does not change the valve's capacity even if the cover is completely frozen.

Possibility of making a version resistant to severe conditions, such as working with particularly aggressive media such as acids, resistant to severe frosts, seaside conditions

- a version adapted to given conditions ensures better work safety. Possibility of using special versions of Petroster valves where standard designs and valves from other manufacturers will not work

Small disc contact surface, reducing the discs' susceptibility to sticking

- the pressure on the disc creates a large ratio of the valve opening force

- greater resistance to freezing and operation in difficult conditions than other structures

Electropolishing of key valve components, reducing the tendency to become dirty and reducing flow resistance through the valve

- longer operation between services, lower risk of valve malfunctions

Better flow parameters than other valves, no risk of condensate accumulation

- no possibility of increasing the valve opening pressure as a result of condensate accumulation

Design ensuring easy and quick service of devices - low operating costs

The weight of the devices allows servicing without the use of hoists

Simple, cheap and trouble-free servicing of devices means increased operational safety thanks to the possibility of more frequent services than in the case of other designs

Optional heating permanently installed as a double-walled space

- does not require disassembly and assembly of the heating system for winter

- possibility of automatic operation, e.g. adjuster with temperature sensor

- no bandwidth changes

contact us

Please contact us. Our team is at your disposal.